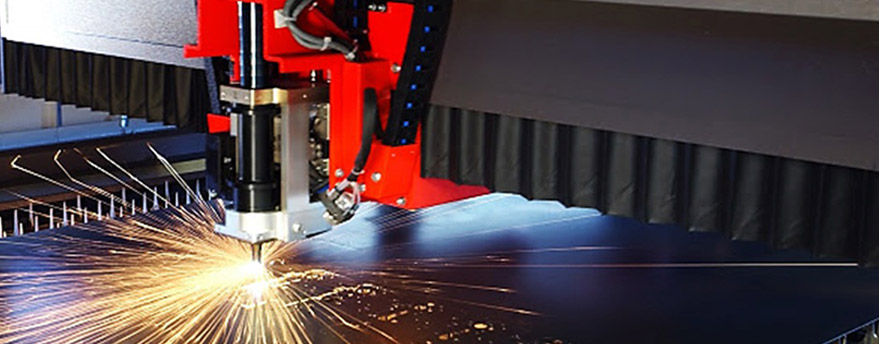

Laser cutting has developed from a high-tech manufacturing process to a considerable common and popular manufacturing process today.

Richinn Technology Pte Ltd is formed to provide an enhanced solution for sheet metal processing to various industries. Our business strategy is to deliver high quality sheet metal parts within the shortest turnaround time. This will help to improve productivity for our customers and thus cost savings.

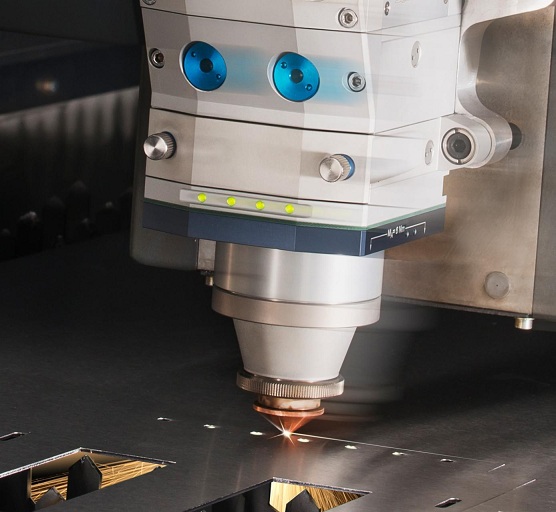

Richinn Tech. has leveraged on the state-of-the-art technology in managing its operation while providing top notch customer care. With the investment of the latest and most sophisticated laser cutting machine, Richinn Tech. is not only able to meet customers’ requirement better, but helps to increase prospective customer’s workflow productivity . As a result, our customers will be able to offer their customers’ high quality finished products timely delivery at reasonable cost.

With the implementation of this high-end technology, Richinn Tech. is able to process thicker materials compared to our competitors. On top of this, Richinn Tech. is also capable to provide 30% faster turnaround time for thinner materials.

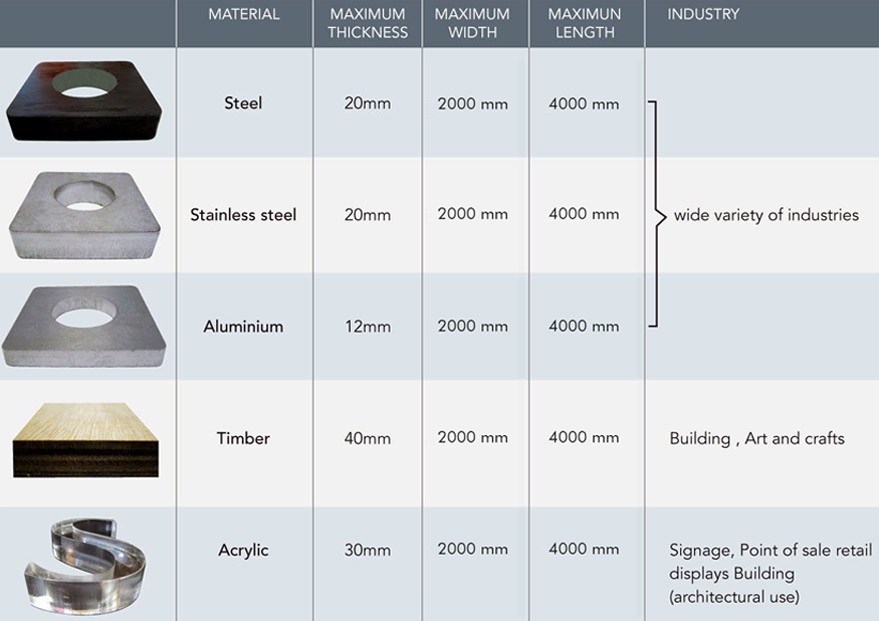

Process Almost Anything

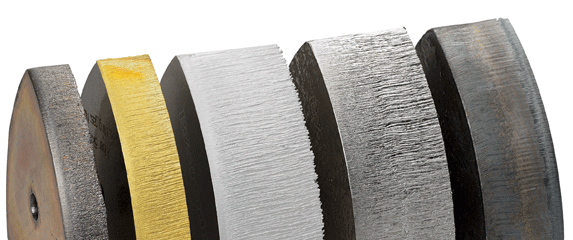

Most metal can be cut by laser with little distortion and with little interference to their chemical composition regardless of their hardness.

Complex shapes are easily cut repeatedly with kerf width of less than 0.2mm hence minimizing material wastage. Small batches or large quantities are simply programmed directly from component drawings, thus eliminating the delays and high cost associated with toolings.

Speed:

Without the need to tool up, short lead times, as well as short production runs become viable. Even “one-off” jobs are economical.

Complex Shapes:

Lasers can cut materials into intricate shapes normally found impossible using conventional manufacturing techniques.

No Distortion:

Laser is a form of light, therefore the non-contact nature of laser process means no mechanical distortion of the workpiece. In addition, the heat generated is so well controlled that there is no or little distortion after processing of the materials.

Most distortions after laser cutting are caused by the stresses within the material. Once they are processed by laser, these stresses are released.