Bending

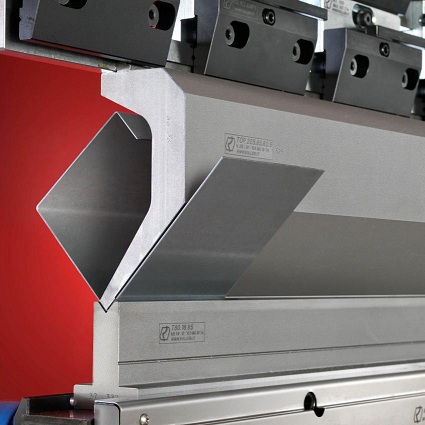

Bending is a procedure for forming a flat, sheet metal work piece. It immediately follows in the cutting processing chain. The work piece lies on a bottom tool with a v-shaped opening. A wedge-shaped tool (punch) presses the work piece into the v-opening and thus bends it to the desired angle.

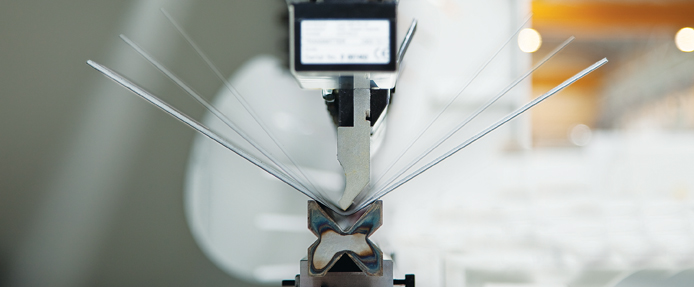

Precision is the most important yardstick for press brakes. Slight deviations from the desired bending angle are physically unavoidable. The bending angle can either be basically inexact or can vary across the entire bending length. There are 2 commonly used bending procedures, 3-point and air bending. Both procedures require compensation systems that would adjust for these errors. In 3-point bending, a hydraulic cushion, which is integrated in the upper tool holder, ensures that the pressing force is distributed evenly across the entire bending length. In air bending, the press brake system with the incorporation of a crowning system that would specifically curved to correct for any deformation occurring during the bending process on the upper and bottom tools.

Richinn Technology has the current capability of processing bending of sheet metal up to 8 metres in length.